Toshiba Electronics Europe GmbH has announced the development of new 1200V silicon carbide (SiC) MOSFETs designed for use in automotive applications, particularly traction inverters.

The new X5M007E120 MOSFET utilizes a manufacturing process that reduces on-resistance (RDS(ON)) per unit area by up to 30% compared to existing methods. Instead of a striped-pattern construction, the new devices arrange the embedded Schottky barrier diodes (SBDs) in a check-pattern to achieve lower on-resistance.

Many SiC MOSFETs can increase on-resistance as body diodes are energized during reverse conduction, leading to reliability issues. Toshiba’s approach prevents body diodes from operating, maintaining the reduction in on-resistance while ensuring reliability.

The rearrangement of SBDs in this device has suppressed body diode energization, and the upper limit of unipolar operation has increased to around double without increasing the SBD mounting area. Additionally, channel density is improved. These enhancements contribute to energy efficiency in applications like motor control inverters.

Reducing RDS(ON) can cause excess current flow during short-circuit operations. By adopting a deep barrier structure, the X5M007E120 reduces excessive current within the MOSFET section and leakage current in the SBDs section during short-circuit operation, enabling durability.

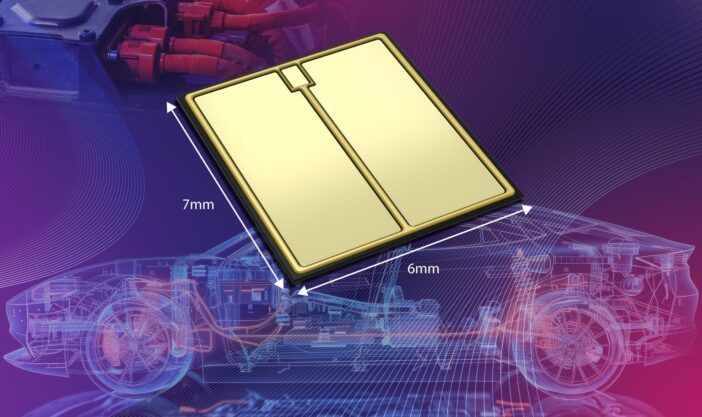

The new X5M007E120 has a VDSS of 1200V and is rated for a drain current (ID) of 229A continuously, with 458A for pulsed operation. RDS(ON) is as low as 7.2mΩ, and the device can operate with channel temperatures (Tch) as high as 175°C. The devices are AEC-Q100 qualified for automotive applications.

Engineering samples are expected to ship during 2025, with mass production samples scheduled to start in 2026. Toshiba will continue to seek ways to further improve the characteristics of its products for applications where energy efficiency is essential, such as electric vehicles.